2022-02-11|admin

Rack and pinion transmission has the characteristics of high speed and high rigidity, so it is widely used in modern mechanical equipment. Common equipment using rack and pinion transmission include: robot seventh axis, truss manipulator, laser cutting machine, woodworking engraving machine and so on.

Next, take the seventh axis of the robot as an example to see how to calculate and select the rack and pinion drive.

The seventh axis of the robot, commonly known as the ground rail, is a walking mechanism used to allow a robot to move back and forth between multiple stations, as shown in the following figure:

Usually, the load on the ground rail is heavy and it needs to move at high speed and long distance, so rack and pinion transmission is often used.

The application cases are as follows:

First, you need to determine the relevant parameters of the device:

|

Drive mode |

load weight |

Maximum speed |

Acceleration |

Positioning error |

Friction coefficient |

|

Single drive |

500KG |

60m/min |

0.2s |

±0.1 |

0.02 |

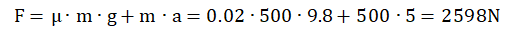

According to the above parameters, the thrust required to accelerate the load can be calculated:

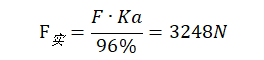

Calculate the safety factor (Ka=1.2) and efficiency (96%) to get the actual required thrust:

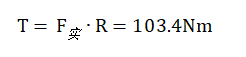

Here, a helical gear with a modulus of 3 teeth and 20 teeth is selected, and the diameter of the index circle is 63.66, and the maximum torque required for the acceleration of the load is calculated:

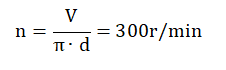

The speed of the gear when the load reaches the maximum speed:

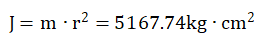

Inertia during load movement:

After getting the above parameters, you can start to select the motor and reducer. Here, Siemens 1FL6067 (2kw) is selected. The motor parameters are as follows:

|

Nominal output torque |

Maximum torque |

Nominal speed of rotation |

maximum speed |

Moment of inertia |

|

9.55Nm |

28.7Nm |

2000rpm |

3000rpm |

30.7kg·cm2 |

In order to ensure that the motor does not exceed the maximum speed of 3000 rpm, the reduction ratio must be less than 10, so we need to choose a reducer with a first-level reduction ratio.

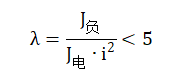

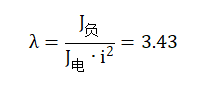

At the same time, the inertia ratio of the load and the motor also needs to be considered. In order to achieve good dynamic performance, it is recommended that the inertia ratio be less than 5 (the maximum cannot exceed 7). According to the formula of the load and motor inertia ratio:

It can be calculated that the reduction ratio is greater than 5, so we finally choose a reduction ratio of 7.

Check:

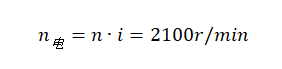

The maximum speed when the motor is working:

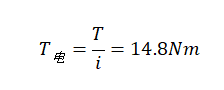

Maximum torque when the motor is working:

Load and Motor Inertia Ratio:

In conclusion, the combination of the motor, reduction ratio and gear can meet the requirements of equipment operation.

When using rack and pinion transmission, the following points should be paid attention to:

1. Try to use pinion gears, which can reduce the diameter of the gear index circle, improve the accuracy, reduce the torque required for the load, and reduce the moment of inertia.

2. Pay attention to the distance between the gear force point and the bearing at the output end of the reducer. If the force arm is too long, it may cause damage to the output shaft of the reducer.

3. In order to reduce noise and improve the stability of equipment operation, limited selection of helical teeth.

4. The end face of the gear needs to be covered with a cover plate to prevent axial play during operation.