Industry news|2022-02-11| admin

1. Standard gear transmission is widely used because of its simple design, good interchangeability, easy manufacture and installation, and because its transmission performance can generally be guaranteed. However, standard gears also have certain limitations, such as:

1. The number of teeth of the standard gear cannot be less than the minimum number of teeth, otherwise undercutting will occur. Therefore, under the condition of a certain transmission ratio and modulus, the reduction of the size and weight of the gear mechanism is limited.

2. The standard gear is not suitable for the occasions where the actual center distance a' is not equal to the standard center distance, that is, a' is not equal to a=m(z'+z")/2. For example, in external meshing, when a'<a, It cannot be installed; when a'>a, although it can be installed,

However, a large backlash will be generated, causing impact and noise, and the degree of coincidence will also be reduced, which affects the stability of the transmission.

3. For a pair of standard gear transmission, although the tooth thicknesses of the two wheels on the index circle are equal, due to the small curvature radius of the involute of the pinion tooth profile, the thickness of the tooth root is thin, and the number of meshing times is large, so the contact strength is low. low bending strength,

The sliding coefficient of the tooth root is large, so the pinion is easily damaged under other conditions being the same.

Due to the above deficiencies of standard gears, it cannot meet the increasingly high requirements of modern production development for gear transmission, so it is proposed to modify the displacement of the gears, resulting in displacement gears.

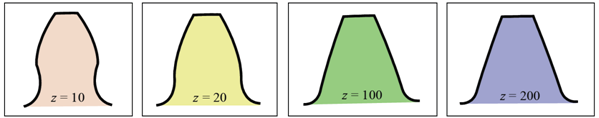

2. The involute tooth profile varies with the number of teeth. The greater the number of teeth, the more straight line the tooth profile curve is. As the number of teeth increases, the tooth profile of the tooth root becomes thicker, and the strength of the gear teeth increases.

It can be seen from the figure that the involute tooth shape of the tooth root part of the gear with the number of teeth is 10 is dug out, and the undercut phenomenon occurs. However, if the positive displacement is used for the gear with the number of teeth z=10,

When the diameter of the addendum circle is increased and the thickness of the gear teeth is increased, a gear strength equivalent to that of a gear with 200 teeth can be obtained.

xm = displacement (mm); x = displacement coefficient; m = modulus (mm)

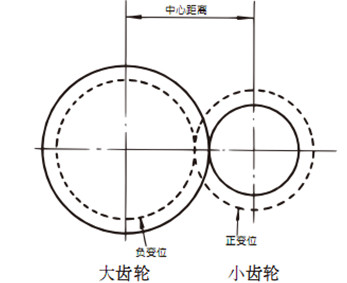

Tooth profile change through positive displacement. The tooth thickness of the gear teeth increases, and the outer diameter (the diameter of the tip circle) also increases. By adopting a positive displacement of the gear, the occurrence of undercut (Undercut) can be avoided. The displacement of the gear can also achieve other purposes, such as changing center

Change the center distance, positive displacement can increase the center distance, negative displacement can reduce the center distance.

Whether it is a positive displacement gear or a negative displacement gear, there is a limit to the displacement amount.

3. Positive displacement and negative displacement

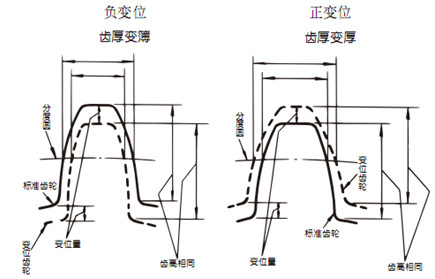

The displacement has positive displacement and negative displacement. Although the tooth height is the same, the tooth thickness is different. A gear with thicker teeth is a positive displacement gear, and a gear with a thinner tooth thickness is a negative displacement gear.

When it is not possible to change the center distance of the two gears, make a positive displacement for the pinion (avoid undercutting) and a negative displacement for the large gear to make the center distance the same. In this case, the absolute values of the displacement amounts are equal.

4. Meshing of the displacement gear

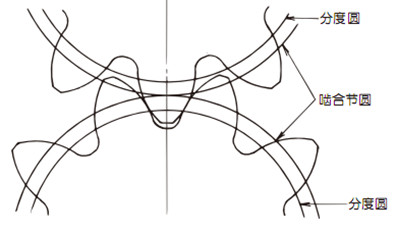

Standard gears are meshed in a state where the index circles of each gear are tangent. The meshing of the shifted gears, as shown in the figure, is tangential meshing on the meshing pitch circle. The pressure angle on the meshing pitch circle is called the meshing angle. The meshing angle is different from the pressure angle on the index circle (the index circle pressure angle). The meshing angle is an important factor when designing a displacement gear.

5. The role of the displacement gear

·It can prevent the undercut phenomenon caused by the small number of teeth during machining.

·The desired center distance can be obtained by displacement.

·When the gear ratio of a pair of gears is large, positive displacement is performed on the pinion gear which is prone to wear to increase the tooth thickness. Conversely, a negative displacement is performed on the large gear to make the tooth thickness thinner so that the lifespan of the two gears is similar.

The above is the relevant knowledge about STRRONSE displacement gear transmission, I hope it can help you, and sz-windrive will introduce more product knowledge to you slowly!